What is vacuum blasting?

The vacuum blasting process, also called vacuum blasting or minimal-abrasive vacuum blasting, differs significantly from conventional sandblasting.

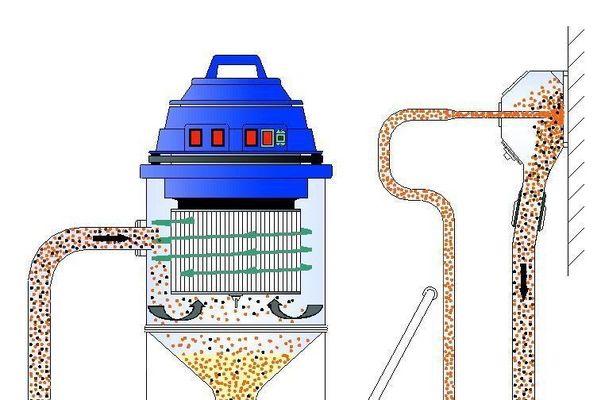

While in the sandblasting process the abrasive is applied with pressure to the surface, vacuum blasting method pulls the granulate out of the container by generated negative pressure in the jet cap and accelerates it in the jet lance to 400 km/h. The high impact speed of the abrasive quickly removes dirt and paint from the surface.

After turning on, the jet cap (6) is placed on the surface (8) and adheres to it by vacuum. With inserting the jet lance (7) into the jet cap (6) the cycle is closed.

By gravity the granules (2) are then passed through from the lower container (1) to a dosing system (3) into the air flow (4). The granules (2) are then transported through a flexible suction house (5) into the jet cap (6). Through the jet lance (7) the granulate impinges on the surface (8) to be worked on. By moving the jet lance (7) the surface can be cleaned quickly and dust-free, stripped or roughened up. The process can be optimally monitored and controlled via 3 vision panels (9). After impinging, the granules (2) and the removed dirt particles are sucked in immediately again.